|

Command Activation

| w |

Qualify→Stylus Manager |

Not Assigned |

| Keyboard |

Main Menu |

Toolbar |

Definition

Re-Qualifying a stylus updates the current stylus with a new size and

MCS location. Re-Qualification has two main functions, to validate the

current size and location of your qualified stylus, or to reposition the

current stylus during the inspection process using a manual indexing

friction probe.

The use of the Re-Qualify command as a validation tool is useful when

it is necessary to perform checks on your stylus database. These

validation tests would look for damaged probes, worn stylus balls,

movement of stylus clusters or any other abnormal conditions that can

adversely affect your inspection results. You may want to create a

Re-Qualify Stylus part program which will report and update changes in

size and location of the stylus.

Re-Qualifying during the inspection process can be used to extend the usefulness of a

friction style articulating probe head such as the Renishaw PH1 or PH8.

The Re-Qualification process can be done manually on a single stylus,

or as part of a motion program which can automatically update the size

and MCS location of all attached styli.

One limitation of using a friction style probe head is that you can not

return to the same articulated position with any degree of accuracy.

Geomet allows the various positions of the probe head to be used in the

part program without establishing new coordinate systems for every

qualified stylus. This can be accomplished by following these basic

steps.

Assuming we are starting with no current stylus qualified, we will qualify the first

position for your inspection using the Stylus Manager as defined in

Qualifying

a Stylus. This will become Stylus Number 1 in your Probe and Sensor Database.

Do not move the stylus, but qualify it again at the same location which becomes

Stylus Number 2. You can also use the

Duplicate

Stylus command to create Stylus Number 2.

Start your inspection with Stylus Number 2 as the active stylus. Do not start your

inspection with Stylus Number 1. Proceed measuring features until it is

required to articulate the probe position. Reposition the probe and perform a re-qualify,

<Ctrl + w>, on the current stylus number 2. You will be prompted to capture data

points on the reference sphere. Once this operation has been completed, you can return to

inspecting new features without any loss of position. This re-qualify step becomes part of

your part inspection and during a program run, you will be prompted automatically.

This can be done to Stylus Number 2 as many times as required to compete your

inspection. Since Stylus Number 1 was not changed, all styli starting with number 2 and

beyond can be used and re-qualified many times.

Should you have moved Stylus Number 1 and performed a re-qualify on it, all

known locations would have moved. This includes established Part Coordinate Systems. The

Stylus Database retains the reference sphere location in the MCS based on stylus number 1.

All Part Coordinate Systems also are referenced to the MCS. Moving stylus number 1 will

cause PCSs to move.

Note: This process can also be used when it is necessary to change styli on the probe

head. For example, you are required to install a stylus with an extension, or install a

small diameter stylus for use on selected features in your inspection.

TIP: When you want to rotate the probe head, or change the stylus to

another size, press the space bar which will "Disable" the probe preventing data

points from entering Geomet. When you have completed the change, press the space bar again

and your probe will enable.

Cautions:

Care should be taken when performing a Re-Qualification using a manual CMM. The

qualification process relies on the XYZ offset from the CMM

Home position for location of the reference sphere. That position is

assigned to stylus number 1.

When you qualify the first stylus, Geomet retains the location based on the center of

the reference sphere in the Machine Coordinate System (MCS). The MCS has an origin point

(X=0.0, Y=0.0, Z=0.0) that has been established either as the power on position for manual

CMMs or the

Home position for DCC CMMs. It is possible to

have an established Home position on some manual CMMs that has that option installed.

Additionally, Re-Qualification assumes the reference sphere has not been moved. If the

reference sphere has been moved, the Geomet function [Recover→Ref Sphere]

should be done.

Stylus Relationships

Stylus number 1 is considered the origin position for the entire stylus database. The

relationship between any stylus and stylus 1 is the MCS offset value in XYZ values. This

offset is applied in calculations when measuring features. By knowing this offset value,

Geomet can measure a single feature with multiple probe tip locations.

Therefore, when Re-Qualifying stylus number 1, all other stylus in the database will be

marked as "Pre-Qual", as shown in figure 1,

see Example below.

|

|

figure 1, Pre-Qual Status |

As shown above, all Stylus starting at number 2 and higher are marked with the Pre-Qual

symbol ( ? ). To update the Pre-Qual size and MCS location of each stylus marked as

Pre-Qual, highlight the stylus and press the <Next> button.

Re-Qualifying an Existing Stylus

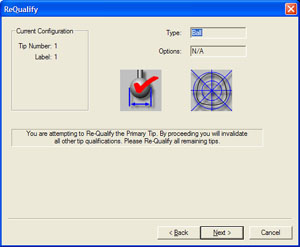

When you start the Re-Qualification process, the first step will show you the previous

stylus definitions, see figure 2.

|

|

figure 2, Re-Qualification Step |

For example, if stylus number 2 was a ball

style when created, this step will show "Ball" in the Type control and you will

not be allowed to change it. Press the <Next> button to proceed to the next

operation.

The next step will depend on the hardware attached to your CMM. As defined in

Qualifying a Stylus, you will be prompted with additional

information such as motorized probe head position or stylus rack position should they

exist on your CMM.

The final step will prompt you to capture the data points required. Once this step has

been completed, the Stylus Database will be updated with the latest size and MCS location

for the selected stylus.

Related Procedures:

Stylus Manager,

Creating

Motion Paths, FCS Manager,

Qualifying

a Stylus,

Develop a Re-Qualify

Program,

Labeling a Stylus,

Deleting

a Stylus,

Duplicate a Stylus,

Stylus db Manager,

Ring Gage

Re-Qualifying,

Choosing a Stylus,

Stylus Edit

Control, Measuring with Multiple Styli

|