|

Summary

During the inspection process, access to a feature is often limited to

the feature's relationship to the current stylus. For example, if measuring

a through bore that is parallel to the surface plate you will need either a

long probe whose shaft is parallel to the bore and can reach the length of

the bore, or the ability to use multiple styli where you can capture data

points entering the bore from both ends.

Using a styli with a long shaft is not the preferred method due to the

degradation in repeatable accuracy and just the fact that it is harder to

capture data points inside a feature where visibility is often obscured.

By using multiple styli that are positioned to access much of the feature

from different entry points, you can spread the data points over the entire

feature assuring the highest possible confidence on the reported results.

The ideal condition is where you have an articulating probe, such as the

Renishaw MH8 or

PH10T. These probe

heads provide repeatable positioning of the styli without the need to

requalify.

The alternative method is the use of a star cluster that has up to 5

fixed styli attached to a common center. The star configuration can be

positioned in the probe head mount to align the styli to the inspection

fixture.

Procedure

Step 1

In this example, we will measure a through bore that lies parallel to the

surface plate and its axis is parallel to the X-Axis of the CMM. To setup

the styli that will be needed, use the Stylus Manager to

qualify the required positions. We will us two

styli, one pointing in the -X direction, the other in the +X direction.

Step 2

|

|

|

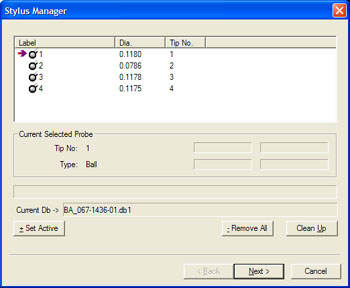

Stylus Manager |

Activate the Stylus Manager and choose the

qualified styli that is orientated toward the -X direction.

Step 3

Select the proper feature to be measured. Here we will use the

cylinder with 16 points. Capture data

points by entering the cylinder from the right side of the cylinder opening.

Spread 8 data points around the full inside surface of the cylinder. When

these 8 data points have been captured, pull the stylus out of the cylinder

an activate the Stylus Manager.

Step 4

The Geomet prompt will still show a cylinder is in progress and that

there are 8 data points still required. When the Stylus Manager is opened

during a feature measurement, you can choose a new stylus and set it active.

Choose the stylus whose orientation is the +X direction and press the

<+ Set Active> button. Geomet will not place a program

statement in the report, but the Current Status banner will update to show

the stylus change.

NOTE: You can use as many qualified styli as needed to measure a

single position. The styli being chosen must be the same probe diameter.

Step 5

Capture the remaining 8 data points on the cylinder from the left

opening. When all data points have been captured, Geomet will report the

cylinder as a single feature.

NOTE: If you are using a DCC style CMM, make sure you have included

the necessary IPs between styli changes to provide safe movement during

automatic inspections.

Related Procedures:

Stylus Manager,

Deleting Styli,

Labeling Styli,

Duplicate a Stylus, Stylus db Manager,

Stylus Edit Control

|