|

Command Activation

<~>

|

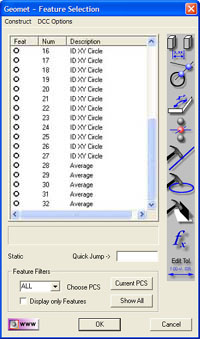

Construct→Feature Selection |

|

| Keyboard |

Main Menu |

Toolbar |

Introduction

Feature Selection provides expanded capabilities to Geomet through the use of random

feature selections. Geomet has been developed over the years as a sequential part

programming tool. This means that operation normally took place

on the last

'x'

number of features. For example if you wanted to obtain the distance between two coplanar

circles you would press the distance key assuming the two circles were the last two

features in your report stack. If they were not, then you would recall the circles to

ensure they were the last two features in the report.

|

| figure 1, Feature Selection Tool |

Feature Selection allows you to select these features anywhere in the report and

perform the distance function. From the Feature Selection dialog, you can perform the

following:

- Distances

- Intersections

- Angles

- Bisects

- Fit Lines

- Fit Circles

- Fit Planes

- Fit Cylinder

- Fit Cylinder from Circles

- Basic Math Calculations

- Edit Tolerance Values in Groups

|

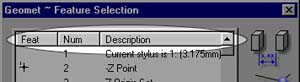

| figure 2 |

To activate the Feature Selector anytime during your inspection process, press the

<~>, key on your keyboard, see figure 2. You can also highlight

features in your inspection report and through the

right-click submenu, choose

[Feature Selection Tool].

How the feature selection tool displays features depends on whether features were

highlight before starting the tool. If no features were highlighted, then the tool will

display all features in your report. Should you have previously highlighted some features,

then only those features will appear in the tool.

There are several filters you can use in conjunction with viewing the features. The

first filter applies to Coordinate Systems. By default, the feature selection will show

all features regardless of PCS affiliation. If you want to choose a specific PCS, use the

drop down box to choose an existing PCS. There is a button labeled <Current PCS>

which will take you directly to the current PCS of the inspection report. The selection

dialog will update to show those features in the selected PCS.

If you want to view only geometric features, place a check next to "Display only

Features". The Feature Selection tool will extract only measured and constructed

features from the inspection report.

Sorting of data is helpful to group together common features. From the Feature

Selector, you can click on the header for the column to sort. For example: click on the

"Feat" column header to sort all 1D points together, 2D points, 3D point, etc.

|

| figure 3, Sorting |

Use the "Num" column to reorder the features in their respective

measurement order. The "Description" column will sort common features together such

as all -Z points and all XY ID Circles. To reverse the order of sorting, click a second

time on the same header and the sort will change from ascending to descending. This can be

very helpful especially in larger programs where you can sort on the "Num" column

twice to view the last features first.

Tips

Why is all this filtering and sorting available? First, we still apply the same

constraints to feature constructions as previous versions of Geomet. For example a -Y

point can not used with a +Z point to obtain distances. Second example: a XY circle from

PCS 3 can not be used with an XY Circle from PCS 5 to construct a line.

Sorting assists the operator in grouping common features or shared Part

Coordinate Systems.

|

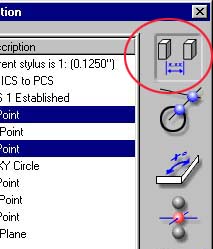

| figure 4, Choosing a function |

Once you have completed your feature selections choose the icons next the selector

window. In the example shown here, the distance button is being chosen. All relationship

functions, Distance, Angle, Intersect and Bisect require two features. Fit features can

have any number of features selected greater than or equal to the required feature

minimum.

Then Geomet will perform your request after validating the rules of constructions. A

new feature or result will appear in your inspection report showing the reference feature

numbers used in the calculations.

|

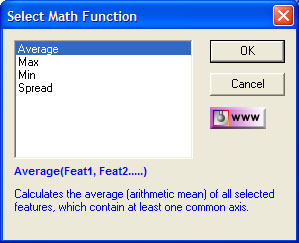

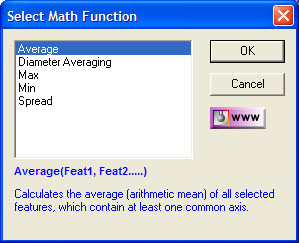

| figure 5, Math Function |

Math functions are designed to provide you with capabilities of obtaining solutions

such as the Maximum, Minimum, Spreads and Average of reported values. To access the math

capabilities, select the features to be used in the calculation and press the math

function button, see figure 5.

|

| figure 6, Basic Math Functions |

The Select Math Function selection box will appear from which you choose the

desired function, see figure 6. When you select a function, in this example

"Average" a description of the function is shown providing you with help on your

choice.

Geomet applies certain rules to ensure that the results conform to standard practices.

Any feature can be selected, however, all features selected must be in the same Part

Coordinate System and that PCS must be the current active PCS, and share at least one

common axis. An example would be selecting the following features:

- -Z 1D Point

- YZ 2D Point

- Sphere

The result would be a 1D Point reported in the Z direction which is the lowest common

axis to all three features.

The new feature created during the calculation are common features that can be used in

other constructions such as additional relational functions (distances, bisects) or can be

used as a component in a Part Coordinate System.

The functions Average, Minimum and Maximum return a 1D, 2D or 3D Point feature. The

Spread function returns a distance similar to the Distance function. To calculate the

result, highlight the desired calculation and left-click on the <OK> button. The

Select Math Function remain displayed for additional calculations.

|

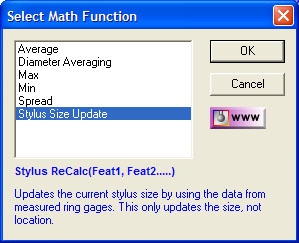

| figure 7, Diameter Averaging |

The Math Functions tool will review the highlighted features in the Feature Selection

Tool. Should they all be a Circle feature type, the Math Functions will include

"Diameter Averaging", see figure 7.

Diameter Averaging will take the diameters of all highlighted features and record the

following in the inspection report:

- Average Radius

- Maximum Radius

- Minimum Radius

|

| figure

8,

Ring gage ReQualification |

This math tool is designed to update the size of

the current qualified stylus based on previously measure Ring Gages,

see figure 8.

Under normal operations, the ball stylus is

qualified against a known reference sphere. During this qualification

process the stylus size and location is calculated. Under most

conditions, the reference sphere qualification process is sufficient for

all general inspection requirements.

However, measure a known ring gage and the

measured diameter normally will be different than the stated ring gage

size. This happens due to variations in probe design and usage. When

qualifying against a reference sphere, the bottom of the probe will

trigger at a different pre-travel distance than a point taken at its

equator.

The Ring Gage Re-Qualification tool uses only

readings around the equator to calculate a high accuracy diameter of the

stylus. The result will only update the size of the stylus, not the

3D location. It is recommended that the Ring Gage be measured

several times as separate records. The math tool will then average all

selected Ring Gage features for a more accurate solution.

To start, set active the stylus to be updated,

see Choosing a Stylus, then follow

these steps:

- Create a Part Coordinate System on your Ring

Gage.

- Measure the Ring Gage as an ID or IR Circle.

- Activate the Feature Selection Tool.

- Highlight the Ring Gage features.

- Select the Math button, see figure 8.

- Enter the Ring Gage Radius when prompted.

- Geomet will report the change in stylus size and

update the Stylus Manager.

NOTE: This process is designed for self

teach operations only and will not create an inspection record which

becomes part of an automated inspection.

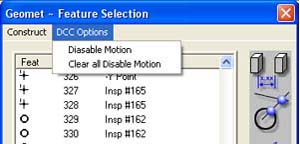

Through this drop down menu you will find access to functions relating to disable or

enable motion for selected features, see figure 9.

|

| figure

9, DCC Options |

DCC Options are only available to DCC style CMMs.

Through this selection process, you can set the "Disable Motion" flag for one

or more features. This instructs Geomet that when running a part inspection program to

drop into manual CMM mode for the tagged features. Geomet will resume DCC operations at

the first feature the disable flag is not set.

The [Clear all Disable Motion] command will remove all disable flags in the entire part

program. Additional information on this feature can be

found here.

NOTE: There are conditions that prevent a feature from being

successfully ran under DCC. An example would be a small diameter where the

positional tolerance is sufficiently large to interfere with the motion map.

By disabling the motion for that feature, the inspection program would drop

into manual, or joystick mode allowing the operator to measure the feature

by hand. When the feature is completed, DCC operations would resume.

Related Procedures:

Disable Motion,

ReRun Program Steps, Tutorial

|