|

Introduction

From time to time during the inspection process it is helpful to drop into manual mode

to capture data points on a designated feature. An example might be a diameter of a

bushing that is inserted into a forging and whose position has a large variance.

In this condition it is helpful for a DCC CMM that is running a part inspection to drop

into manual mode to allow the operator to control the capturing of data points. Then upon

completion of the feature, return to DCC control and resume the inspection

Applying the Disable Motion Flag

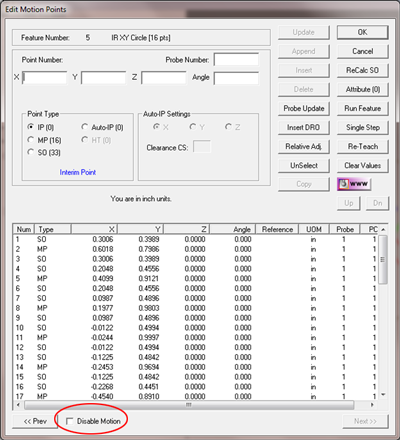

Applying the Motion Disable flag can be done through two different methods. The first

of these methods involves the Motion Edit dialog, see figure 1. This method

allows you to flag one feature at a time to disable motion, see

Edit

Motion for additional information.

|

| figure 1, Motion Edit Dialog |

In the lower left section of the Motion Edit Dialog, you will find a check box

labeled "Disable Motion". Place a check here to force this feature into manual

mode during the inspection process. All current motion assigned to this feature will

remain visible in the Motion Edit control and during program execution will not be acted

upon. This allows switching the Disabled Motion on and off depending on conditions.

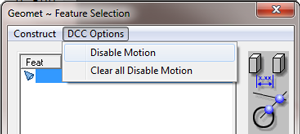

In method 2, you can use the

Feature Selection Tool which

will allow you to attach many Disable Motion Flags in one operation, see figure 2.

|

| figure 2, Feature Selection Tool |

When using the Feature Selection Tool, highlight in the

displayed list the features you would like to toggle the Disable Motion Flag.

Once the highlighting is completed, open the drop down menu and choose [DCC

Option→Disable Motion]. It is important to remember when selecting this command

that it is a toggle which sets or removes the disabled flag.

Should you select the command [DCC Options→Clear all Disabled Motion], all

Disable Motion flags will be cleared from the entire part inspection regardless if was

highlighted in the list or not.

Disabled Motion Behavior at Inspection Time

When Geomet is executing a part inspection program, it is constantly looking for the

Disable Motion flag. Should a feature with the flag be found, Geomet will drop into manual

mode to allow the operator to control the capturing of the required data points for the

feature.

When the required number of motion disabled features have been completed, Geomet will

display a targeting tool that shows the location of the first motion point of the

next

feature. The targeting tool shows the XYZ relative position to that point and the operator

should joystick or manually drive the CMM to where the targeting box shows all zeros, or

near zero. At that time, press the <Continue> button on the target tool and Geomet

will return to DCC and resume part inspection.

|