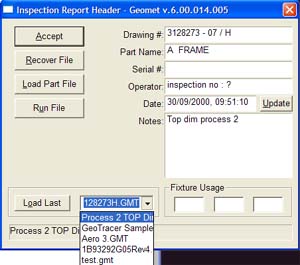

The Header Dialog provides access to the Drawing Number, Part Name, Serial Number,

Operator, Date and optional Notes. The Date field will report the current time and date

when starting a new report. The time and date can be edited by entering a new value or

updated with the <Update> button.

When starting a new inspection report, the previous values will be carried forward with

the exception of the time and date which will report the starting value. This is

especially helpful when repeating a part inspection.

The <Accept> button closes the Header Dialog and attaches the data fields to the

inspection report.

The <Recover File> button is available when returning to the previous inspection

that might have closed inadvertently. Geomet maintains a companion file when teaching a

part inspection. Should a condition arise, such as a program crash caused by events such

as a power failure, the Recover File operation will read in the previous completed steps

and the inspection can continue.

There are some limitations to a recover operation that affect the success of a recover.

For example, not all manual CMMs have a repeatable home position and when you recover, see

Setting the Home Position. If the CMM did not have a repeatable

Home position, the recovered XYZ values will not match the XYZ values when the inspection

was first done. To overcome this condition, perform the recover file operation and then

Run the file to rebuild the coordinate systems and feature actual values.

On DCC CMMs, the home position is repeatable and after a recover operation, you can

continue building your part inspection.

The recover file operation is only available when the "Save Recover Mode" is

active. By default Geomet saves the recover file. You can elect to turn off the feature by

placing a 'Yes' next to Turn off Inspection Recovery Mode in

System

Options.

As the name sounds, the command will prompt you to load a part program. Should you have

a part program opened, you will be prompted to save you current inspection.

This command will commence running the part program currently open. This is the same

command as [File→Run] from the main drop down menus.

The Header Dialog maintains a record of the last 5 inspections opened. To provides fast

access to one of these files, select from the drop down list the inspection program and

select <Load Last>, see figure 2.

|

| figure 2, Load Last Selection |

When a new inspection is created, the data and time is

written into the record and does not change when the program is opened or

edited. To override the data and time, press the <Update> button and the

Date: field will update.

Pressing this Information / Help button, Geomet will attempt

to connect to the Internet and display the help page associated with the

Inspection Header tool.

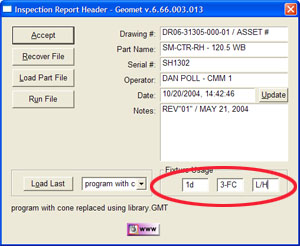

|

| figure 3, Assigning Fixture Data |

An example on using these Fixture fields would be to

identify what machining center a production part was manufactured on.

The manufacturing department may have many machining centers all making

the same part. We had one company that used over 50 machining centers

all making the same part! When it came time to measure, the operator

would type in the note section of the header the machining center ID.

Unfortunately the notes section of the header does not

provide any sorting capabilities. The Fixture Usage fields do. When

inspecting the production, enter the machining center ID in the Fixture

Usage fields and then sorting can be done to group all production

inspected on the machining center it was produced on. This is helpful

when performing SPC on production.

By default, Fixture Tracking is not active. To activate

fixture support navigate to System Options

and change to 'Yes' next to Use the fixture

data fields in the program Header.

Geomet allows the tracking of up to 3 unique inspection identifiers for a

part being inspected. We call these identifiers “Fixture Usage” from the

original purpose where a fixture ID was added to the inspection report.

An example on using these Fixture fields would be to identify what machining

center a production part was manufactured on. The manufacturing department

may have many machining centers all making the same part. We had one company

that used over 50 machining centers all making the same part! When it came

time to measure, the operator would type in the note section of the header

the machining center ID.

Unfortunately the notes section of the header does not provide any

sorting capabilities. The Fixture Usage fields do. When inspecting the

production, enter the machining center ID in the Fixture Usage fields and

then sorting can be done to group all production inspected on the machining

center it was produced on. This is helpful when performing SPC on

production.