|

Introduction

As the name implies, Process Control Tolerance (PCT)

is a form of controlling manufacturing processes by monitoring production

and automatically reporting conditions that require correction of the

process before non-compliance issues arise. Traditionally a

feature attribute has a single tolerance value that, when exceeded, was

reported only as non-conforming. By the time a non-conformance had been

identified, the manufacturing process may have produced parts that may now

require expensive repairs.

|

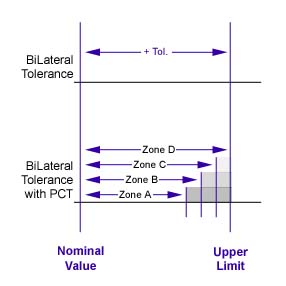

| figure

1, PCT Tolerance Zones |

Using PCT allows the inspector to establish different but simultaneous

tolerance zones for position and size of features. For example the size of a

bore might be specified as 1.000 +/- .001. Under PCT controls the controls

values might look like:

Nominal [Zone A] /

[Zone B] / [Zone C] / [Zone D]

-or-

1.000 [+/-.0007] / [+/-.0008] / [+/-.0009]

/ [+/-.001]

As shown in figure 1, We break down the tolerance band

into zones of control. Each zone is identified by Geomet as Zone A / Zone B

/ Zone C and Zone D.

Tolerance Zone Description

The actions required for each tolerance zone is

defined by your companies quality procedure. The zone description below are

suggestions only.

Zone A: This portion of the tolerance zone is

considered in compliance and requires no action. The default value for this

zone is 70% of the allowable tolerance, but may be changed to any desirable

percent of tolerance.

Zone B: Is the portion of the tolerance

zone that exceeds the limit established by Zone A. It is monitored as a

first response to provide corrective action to bring the production process

back under the trigger limit. Production is still within tolerance limits.

The default limit of this zone is 70% - 80% of the allowable tolerance zone.

Zone C: This portion of the tolerance zone

requires immediate action to correct a potential production problem. The

production is still within the tolerance limit, but beyond a trigger zone

that requires immediate attention. The default limit for this value is 80% -

90% of the allowable tolerance zone.

Zone D: This level equals 90% of the allowable

tolerance zone and identifies the production as non-conforming that requires

a material review.

|

Zone |

Suggested Action |

A

B

C

D |

No action required.

Notify Manufacturing and monitor.

Notify Manufacturing and review

process.

Notify Management and adjust

process. |

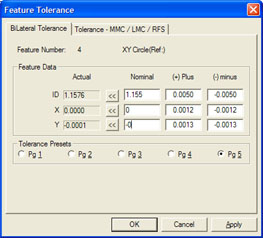

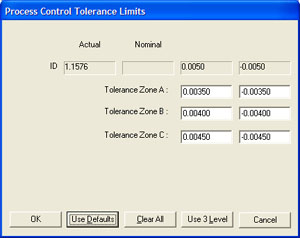

Applying PCT to a Feature

You access the PCT dialog when you apply standard

tolerance from within Geomet. In figure 2, the toleranced feature is a

standard ID XY Circle. The tolerance box will have buttons labeled as

next to

the Actual value. This is the button used to start the PCT dialog. next to

the Actual value. This is the button used to start the PCT dialog.

|

|

| figure 2,

Tolerance Dialog |

figure 3,

PCT Dialog |

Process Control Tolerance Application Screen

Each zone can be edited with a custom value or the <Use Default> button

can be selected to use the predefined percentages for each zone,

see System Options. There

exists a validation to exit this dialog, where

the zones must be A < B < C <= D to prevent zone

overlapping.

If you require a tighter control, select <Use 3 Level> which will

compress the allowable tolerance limit by eliminating Zone C and defining it

as the non-conformance limit. This will have the same effect as removing the

first notification level when the trigger value has been exceeded.

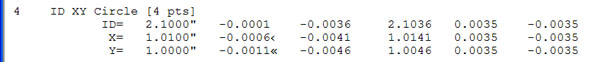

Reporting of Process Control Tolerance

When a feature is being reported, the Dev. Tol. column

will indicate which zone the results fall within. When a value is in Zone B

you will see a number representing the amount beyond the trigger value. If

in Zone C then the value will be tagged with a symbol: <. If the value is in

Zone D, then the symbol is: << and special care should be taken to segregate

the production.

| Nominal Value |

Reported Value |

Deviation |

PCT Symbol |

Zone A |

Zone B |

Zone C |

Zone D |

|

PCT Reported Symbol by Zone |

|

none |

< |

<< |

Standard OOT Reporting |

| 2.1036 |

2.1000 |

0.0036 |

|

+/-0.0035 |

+/-0.0040 |

+/-0.0045 |

+/-0.0050 |

| 1.0141 |

1.0100 |

0.0041 |

< |

+/-0.0035 |

+/-0.0040 |

+/-0.0045 |

+/-0.0050 |

| 1.0046 |

1.0000 |

0.00046 |

<< |

+/-0.0035 |

+/-0.0040 |

+/-0.0045 |

+/-0.0050 |

| |

|

|

|

|

|

|

|

|

|

|

Example of a Geomet Report using

PCT |

In the footer of the report, there will be an assigned

classification showing a large letter corresponding to the maximum zone

reached. There will also be a summary line listing the total count of all

attributes that have PCT applied. The summary line will report: Total

Inspected count followed by a count for each zone.

|

| PCT Summary Report |

The printing of the summary line can be toggled between printing and not

printed by accessing the Report Config tab in System Options,

see System Options

for a complete description.

To print, place a check next to Print Report Summary.

|