|

Command Activation

| <Alt + Shift + B> |

Analysis→Feature Profiler |

|

| Keyboard |

Main Menu |

Toolbar |

Definition

The Planar Profiler offers the user a visual display

of the data points used in the measurement of a plane. The Profiler can be

used during the capturing of the data, or used as a tool to review the data

points after a plane has been measured.

The resulting display shows the relationship of the

data points localized to the measured plane, or absolute to the Part

Coordinate System.

Activation during the Inspection Process

To view the results of the calculated plane while

capturing data points, start the Planar Profiler, then start the Plane

function. It is suggested that you start the plane function with a large

number of data point such as 999. As you capture data points, the display

will update and the plane results will be displayed.

When you have captured sufficient data points, press

the Terminate function key <F5>.

If you start capturing data points with showing the

Planar Profiler, press <Alt + Shift + B> and the profiler will appear with

the data points already captured.

Reviewing a completed Plane

You can review the profile of a previously measured

plane by highlighting the plane in the report area and then choose one of two

activation methods. In the first method, right click and from the sub menu

that appears, choose "Feature Profiler". The second method uses the main

drop down menus, locate [Analysis→Feature Profiler].

Planar Profiler Display

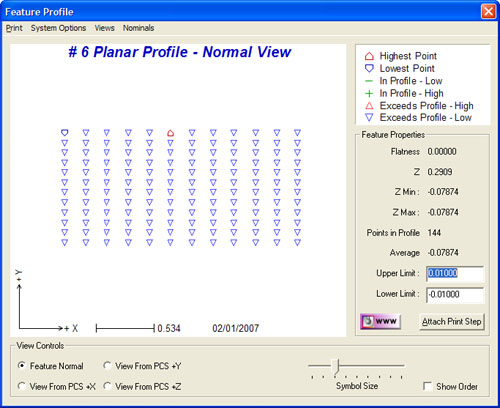

|

| figure 1,

Planar Profiler Display |

The Planar Profiler Display shows the relative

relationship of the captured data points that were used to fit the reported

Plane feature. In figure 1, we have 8 data points shown in a circular

pattern. Each data point is displayed with a identifying symbol which is

described in the Symbol Legend.

During the actual capturing of the data points, the

display will update with the recalculated information about the plane. The

display will resize automatically to ensure all data points can be seen.

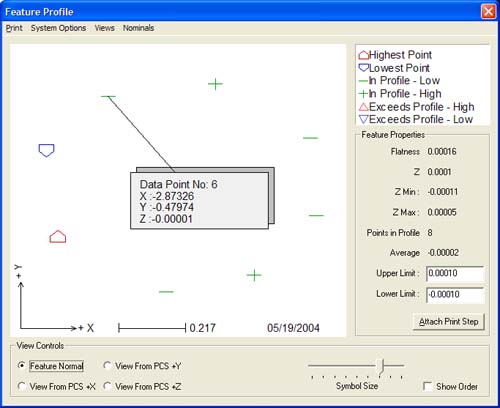

Viewing the XYZ Position of Data Points

It is possible to view the Part Coordinate XYZ

position of an individual data point. To perform this operation, right click

over the data point symbol and a popup box will appear that reports the

position, see figure 2. In this example, we right-clicked while

positioning the mouse pointer over the data point.

|

| figure 2,

Data Point Information |

There are four viewing modes:

The display of the data while orientating to the calculated plane normal.

This mode is the most common mode and illustrates the high and low areas of

the plane. This view would closely illustrate a plane's flatness.

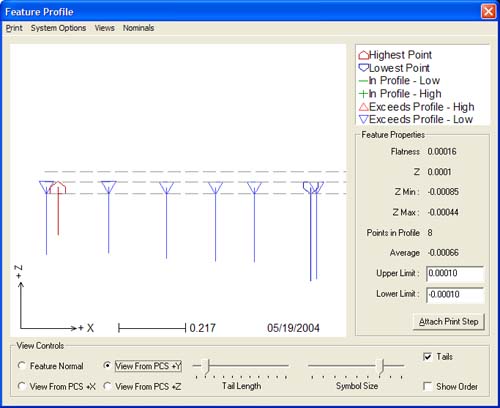

View From PCS +X, +Y and +Z

These views offer

a view that is constrained by the current Part Coordinate System. The

application would closely resemble the location of the data points in a

profile band referenced off the Part Coordinate System, see figure 3.

|

| figure 3,

Planar Profiler Viewed from the PCS |

Comparing the Views

In figure 1, we have all data points within the

designated profile of +/- 0.0001. This differs from the data point display

in figure 3 where it shows all data points beyond the profile band limit.

In figure 1, we are evaluating the individual data

points directly against the localized area of the plane simulating a dial

indicator moving over the plane with its zero set at a point within the

measured area. Each data point is then compared to that zero point without

regard to the actual reported position on the current Part Coordinate

System. This process is comparable to the inspection technique used to

measure flatness.

in figure 2, we perform a similar test on each data

point also using a dial indicator concept. In this view we set the zero of

the indicator where it crosses the reported axis of the Part Coordinate

System. Then move the indicator over to the individual data points and

record the change in reading. This process would be comparable to the

inspection technique used to measure the profile.

Display Controls

There are basic display controls that change the look

of the data being reported.

Symbol Size

As it describes, this slider will

scale the symbols being displayed for better viewing. Symbol Size is available

in

all views.

Tail

This check box is available only when

viewing from a PCS axis. By placing a check here, the display will show the

profile limits and exaggerated whiskers for each data point.

Tail Length

This slider is available only when

viewing from a PCS axis. This will change the exaggeration of the tails with

regard to the profile limits.

Show Order

When checked, all data points will

be displayed with a number corresponding to the order it was captured during

measurement.

Menu Commands

There are 4 drop down menu titles available in the

Planar Profiler. These control the behavior of the printing and displaying of

data.

Print...

This command prints the current

display on demand.

Page Setup

Used to control the printer

characteristics.

1-Up

Sets the preference for the displayed

feature to print one view per page.

2-Up

Sets the preference for the displayed

feature to print two views per page as defined in the Planar Profiler

setup. This mode is helpful when you want to view the feature normal and

one PCS axis view on a single sheet of paper.

System Options

Set Colors

You can set colors

for the six individual point-type definitions.

Print Heavy Lines

This informs the

profiler to print with 2x heavy lines. This is helpful when printing

from high resolution printers where the printing of a 1 pixel wide line

appears faint or hard to see.

By selecting this option,

all data points will be

printed when a complete inspection report is requested. The printout

will include the deviation distance to the plane and its XYZ location in

the Part Coordinate System.

Views

View 1 - Upper

Choose the view to be

printed in the first position of the 2-Up or 1-Up report.

View 2 - Lower

Choose the view to be

printed in the second position of a 2-Up report.

Nominals

Not activated.

Attach Print Step

The Attach Print Step will append a program step to

your Inspection Report that will print the Planar Profile report during the

execution of the inspection program. Do to the graphical nature of the

report, we suggest these program statements be placed near the bottom of the

inspection report. Most printers will slow down when printing in graphic

mode.

Related Procedures:

Data Point Report,

Plane,

Planar Profile Tutorial

|