Helmel Engineering Products, Inc. Customer Support -- Tech Note #2

Multi-Point Feature and CMM Inherent Errors:

Applies to: All Levels of Geomet, Geomet 501

Last updated:

Tuesday December 08, 2009.

NOTICE

Information contained within this document is subject to change without notice. No part

of this document may be reproduced or transmitted in any form or by any means, electronic

or mechanical, for any purpose without written authorization from Helmel Engineering

Products, Inc.

This document contains proprietary subject matter of Helmel Engineering Products, Inc.

and its receipt or possession does not convey any rights to reproduce disclose its content

or to manufacture, use or sell anything it may describe. Reproduction, disclosure or use

without specific written authorization of Helmel Engineering Products, Inc. is strictly

forbidden.

© Helmel Engineering Products, Inc. 1985 - 2006. All right reserved.

GEOMET®, MICROSTAR® are trademarks of

Helmel Engineering Products, Inc.

Introduction

Technical Note #2 - Multi-Point Feature Inherent Errors

Published October, 14, 2003

Edward R. Yaris - Software Development Manager, Helmel Engineering Products, Inc.

Commonly found Errors

- CMM Calibration Errors

- Probing Errors

- Operator Influences

- Data Point Spread

System Errors

In all multi-point features, the ability to report accurate and repeatable

results are subject to the quality of the gathered data points. Influencing

your measured results will be the stacking of inaccuracies within your

measuring system generated by the commonly found errors listed above.

Coordinate Measuring Machine

Scale Error

The CMM has inherent inaccuracies such as axial linear error and mechanical

limitations on squareness, parallelism and perpendicularity. Every CMM has a

scale attached to each axis of movement. This scale can be a mechanical /

optical or laser configuration. In the case of a mechanical / optical there

exists positioning error which CMM manufacturers will attempt to compensate

for through hardware or software.

For example when a scale is installed, it will be compared to a master

scale or laser. The CMM will be positioned along the scale at different

points and the reported position will be compared to the master. If the

position reported by the laser was 10.00000 and the CMM reported 9.99875 The

difference will be the linear inaccuracies of the scale at that position. In

a single linear compensation, a scale factor will be applied to the CMM’s

position feedback to correct for the error. However, this method of

compensation works with the overall average and does not correct for local

inaccuracies along the scale.

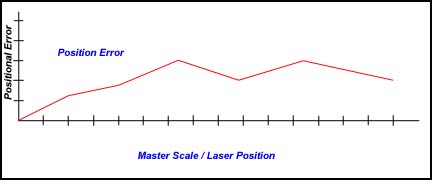

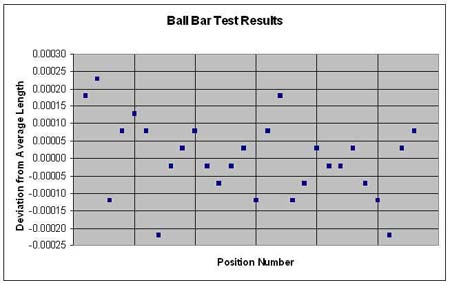

The chart below demonstrates the Position Error measured compared to a Master Scale or

Laser. The scale along the left side illustrates the deviation error.

|

| figure 1, Original Positional Error |

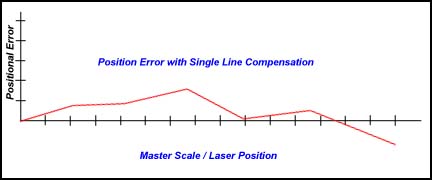

After single line compensation has been applied the deviation error has been minimized

to create a more accurate position.

|

| figure 2, Single Linear Compensation Applied |

One limitation in single line compensation is that the variances along the

scale can not be individually removed. Therefore the single line

compensation method only averages out the entire scale without regard to

multiple position errors. When the CMM is positioned along the scale, some

error characteristic will still be built in.

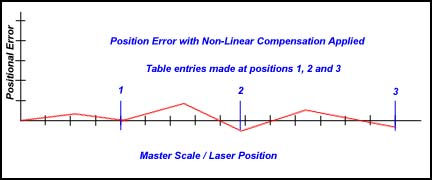

Non-Linear Scale Compensation

Another method to minimize scale-positioning error is the Non-Linear

method. This method builds a table of compensation values that can be

measured and created along the various undulations along the scale. It

requires that the CMM has a reproducible home position for all axes. The

chart below illustrates a non-Linear method applied to the same scale shown

above. The error has been reduced further.

|

| figure 3, Non-Linear Compensation Applied |

As with any linear compensation method, if the scale is not mapped out over

every position, then an error will always be present influencing your

results.

Mechanical Intrinsic Accuracy

The next error that a CMM can have is called intrinsic accuracy, the

mechanical accuracy of the CMM. These include Squareness, Perpendicularity

and Parallelism of the structure of your CMM. If the X-axis is not

perpendicular to the Y-axis, then when the probe is moved along the X-axis a

deviation in Y will occur. To test for this, place a certified square down

on the CMM base. Place a .0001” or better indicator on the probe bar and

lock the Z and X-axes from moving. Move the CMM in the Y-axis with the

Indicator in contact with the square. Set the square edge parallel with the

Y-axis travel until no movement is shown on the indicator. Unlock the X-axis

and reposition the indicator so it contacts the square and lock the Y-axis.

Move the indicator along the X-axis and you should not see movement on the

indicator dial.

Repeat this procedure in the front and back location on your CMM to

ensure the X to Y-axis relationship is perpendicular thoughout the measuring

envelope. An additional test would be to raise the square to the highest

point within your measuring cube and repeat the procedure.

Should you see a deviation, then your CMM is not square in the XY

plane. Any measurements taken will have an inherent inaccuracy.

The Z-axis should be perpendicular to the CMM base. To test this, place a

.0001” or better indicator on the probe bar. Place a certified square on the

CMM base with the surface parallel to the Y-axis. Lock your X and Y-axis

with the indicator in contact with the square. Move your Z-axis up and down,

you should not see any movement on the indicator. Now repeat the test with

the surface of the square parallel to the X-axis.

Should you see a deviation, then your CMM is not square in the ZX

and / or YZ plane. Any measurements taken will have an inherent inaccuracy.

BallBar Test for CMMs

One method to accurately evaluate axis to axis relationships is found in the

B89.4.1,

Methods for Performance Evaluation of Coordinate Measuring Machines published by

ASME International. This Standard

establishes requirements and methods for specifying and testing the performance of

coordinate measuring machines (CMMs) having three linear axes perpendicular to each other

and up to one rotary axis positioned arbitrarily with respect to these linear axes. In

addition to clarifying the performance evaluation of CMMs, this Standard seeks to

facilitate performance comparisons among machines by unifying terminology, general machine

classification, and the treatment of environmental effects.

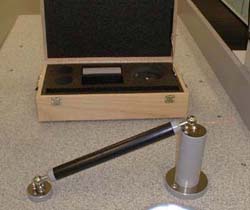

The Ball Bar consists of a temperature stabilized bar with two high precision spheres

mounted at each end, see figures 4 and 5. The length between the spheres is not

necessary to be known. The Ball Bar is positioned within the measuring area of the CMM in

28 different positions as described in ASME B89.4.1.

|

|

| figure 4, Ball Bar Set |

figure 5, Evaluated Ball Bar Position |

The process of gathering data involves the measuring of each sphere and

calculating the direct line distance between them. One advantage of this

method over other methods, such as a step gage, is the averaging effect of

the probe lobe errors. In any given direction around the traditional touch

probe, there exists a lobing error that can be measured, but not effectively

removed from a feature calculation. By capturing data points evenly around

the sphere, the lobe error variations are not removed, but averaged out to

obtain a closer size and location reporting of the actual sphere.

Once all 28 positions have been calculated, they can be entered in a Excel spreadsheet,

download. The average of all 28 positions is

first obtained and a companion column of actual - average is calculated. These values are

then plotted as shown in figure 6.

|

| figure 6, Plotted Ball Bar Test Results |

The Maximum and Minimum values are found from the deviation column. The

spread between these values is considered the working tolerance. This value

is often reported as the volumetric accuracy of a CMM. It should be noted

that the length of the ball bar is often a small fraction of the actual

measuring area. Therefore, the reported working tolerance only reflects the

area the cubic size of one ball bar length in the X, Y, and Z and should not

be used to define the entire CMM.

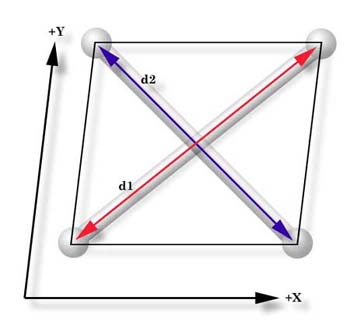

|

| figure 7, X / Y squareness |

In figure 7, we can visualize how to interpret the Ball Bar tests. We can see the

direct effect of a squareness deviation of the X versus Y axis. The distances of the

measured lengths, d1 and d2, should be equal when the

CMM has been properly setup. As the illustration shows, d1 being greater

than d2 demonstrates that the relationship between the X and Y axis are

not perpendicular. When properly interpreted by a trained calibration engineer, all 28

positions will effectively provide a picture of the intrinsic characteristics of your CMM.

Many CMM manufacturers have abandoned building intrinsic accuracy in

favor of 3D software compensation. This allows building of a CMM with little

attention to the accuracy of the assembly. The accuracy is acomplished by

mapping the CMM with a known standard, such as a laser, then providing 3D

compensation algorithms to correct the inherent errors. However using only a

laser does not remove all the inherent inaccuracies within the entire

measuring cube.

There is no correct answer as to which method delivers a more accurate

CMM. In both cases, the ability to perform field calibrations often becomes

an economic cost the user must absorb. To perform a field calibration by

mapping the CMM with a laser system is a higher cost than adjusting for

intrinsic accuracy.

Probing System Errors

Every probe system introduces inaccuracies to your data point gathering.

These include capture speed, lobe errors, stylus lengths and probe contact

pressure. Understanding the errors within the probe system can be very

difficult. Most electronic touch probes have no index position when

installed on a CMM and can rotate to a new location moving the lobe error.

Additionally, electronic touch probes are a simple switch and can not

determine the approach vector at the point of contact. This simple fact

makes it very difficult to map out probe errors.

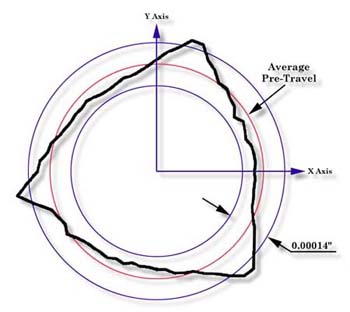

|

| figure 8, Lobing Error |

Lobe errors are mechanical limitations to the probe head. Lobes can have an

error in excess of .0001” deviation when capturing a point moving at 0°

compared to capturing a point at 60°. As shown in figure 8, the lobe error

pattern is triangulated based on the mechanical layout of the kinematics

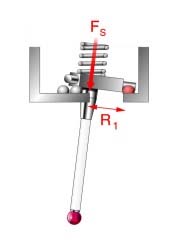

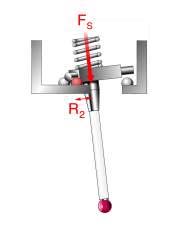

probe alignment, see figure 9. The touch probe can be described as having

low and high force directions when capturing a trigger, see figures 10 and

11.

|

|

|

| figure 9, Force Direction |

figure 10, High Force Dir. |

figure 11, Low Force Dir. |

Stylus lengths will add additional error to your system. A short length of

about 10mm will not influence your data points, however a 100mm length will

increase the error 10 fold to the lobe deviation. If you need to extend your

stylus, we recommend the Renishaw PEL family of extensions. These are

extensions that mount between the probe head and probe body.

When the Trigger Force pressure is set too high, the probe error will

increase exponentially! Most mechanical probes allow you to adjust the

tension applied to the trigger mechanism, see manufacturers technical

manual. Some touch probe models, such as the Renishaw TP20, offer

interchangeable modules with a preset trigger force. By increasing the

pressure, you force the probe to trigger at a higher pressure that

introduces stress and deflections in the stylus tip and extension.

Strain-gauge or piezo designed probes, such as the Renishaw TP200,

minimizes the lobe error by eliminating the mechanical kinematics design.

However, these gauges are susceptible to speed changes and the actual

contact speed should be stable and consistent. Probes that use this

technology should not be considered for manual CMMs.

Operator Influences

Finally the operator will provide the greatest error. If the operator

captures data points with an inconsistent speed, repeatability errors are

introduced. To test for speed difference, lock the Z and X-axes on your CMM.

Place a part on your CMM and measure a +Y point. Increase the speed at which

your capture points. At a certain speed you will begin to see variances in

the reported results.

Other operator related issues include where you hold the CMM. If you have

a large CMM, probing while holding the probe bar just above the probe will

act differently that when you are holding as far up the probe bar as

possible. The probe bar is a lever, and by moving that lever you are placing

strain on the superstructure of the CMM. If you gather data points before

the CMM has ‘settled’ you will get unreliable data points.

Data Point Spread

When measuring multi-point features, how you spread the data points will be

the single greatest influence on the accuracy and repeatability of the

feature. For example, if you capture data points on a circle using only a

15° sweep, the results are unreliable and not repeatable. If those same

points were captured over a 300° sweep, the results would be accurate, see

figure 12. The same holds true for Planes spheres, cylinders and cones.

Cylinders and cones require a proper spread over the length otherwise the

axis of the feature will not be reliable.

|

Arc (degrees) |

Center error |

Radius error |

| 180 |

0.00014 |

0.00000 |

| 120 |

0.00028 |

0.00014 |

| 90 |

0.00048 |

0.00034 |

| 60 |

0.00104 |

0.00090 |

| 30 |

0.00409 |

0.00395 |

| 20 |

0.00914 |

0.00899 |

| 10 |

0.03549 |

0.03535 |

| 5 |

0.12823 |

0.12810 |

| figure

12, Circle

deviations from reduced sweep arc |

Imagine capturing two points on a line only .25” apart with a probing error

of .0001”. The resulting line would have a repeatability error of .040” over

5.000” or 0.4584 degree! If that line were used as part of the Part

Coordinate System, then all subsequent features would have questionable

accuracy.

|