| |

|

| |

Definition |

| |

This Stylus Size Update math function inside the Feature

Selection Tool, is designed to update the size of the

current qualified stylus based on previously measure

Ring Gages.

Under normal operations, the ball

stylus is qualified against a known reference sphere.

During this qualification process the stylus size and

location is calculated. Under most conditions, the

reference sphere qualification process is sufficient for

all general inspection requirements.

However,

measure a known ring gage and the measured diameter

normally will be different than the stated ring gage

size. This happens due to variations in probe design and

usage. When qualifying against a reference sphere, the

bottom of the probe will trigger at a different

pre-travel distance than a point taken at its equator.

The Ring Gage Re-Qualification tool uses only

readings around the equator to calculate a high accuracy

diameter of the stylus. The result will only update the

size of the stylus, not the 3D location. It is

recommended that the Ring Gage be measured several times

as separate records. The math tool will then average all

selected Ring Gage features for a more accurate

solution. |

| |

|

| |

Setting up the ring gage |

| |

For greatest accuracy,

set the ring gage directly on the CMM surface

plate or elevated using parallels. Set a Part

Coordinate System directly on the Ring Gage with

the origin in the center.

Measure the

Ring Gage multiple times. The average of all

inspection results will be used when determining

the stylus tip diameter.

|

| |

|

| |

Calculating

the Stylus Diameter |

| |

Select the

measured results of the Ring Gage in the

inspection report. Activate the Feature

Selection tool

to access the math functions.

Select the

measured results of the Ring Gage in the

inspection report. |

|

|

| |

Activate the Feature

Selection tool

to access the math functions.

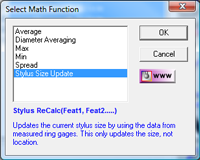

Press the 'fx'

button to access Math Functions. Select "Stylus

Size Update" and press the

button.

|

|

|

| |

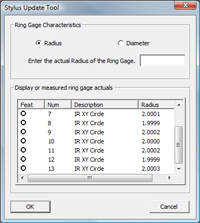

In the Stylus

Update Tool, select the Ring Gage nominal of

Radius or Diameter using the button selectors.

Enter the Rang Gage nominal and press the

button. button.

|

|

|

| |

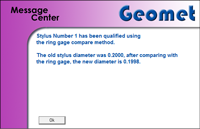

A message will be

displayed showing the original stylus diameter

and the new calculated size. Press  button to complete the process.

button to complete the process. |

|

|

| |

Precautions |

| |

Care should be

taken to understand that updating the stylus

size using the Ring Gage method does not correct

for XYZ offset between the reference stylus,

normally number 1 and the current stylus.

Using the Rang Gage method is best suited

when measuring features that require high

accuracy and generally working in the same plane

as the orientation of the Ring Gage.

The

use of the Ring Gage calibration method is not

recommended for use on manual CMMs. Touch Probes

and CMM hysteresis greatly affects the

repeatability. If the operator has a consistent,

even movement in capturing data points, then

these errors are reduced. To better understand

CMM system limitations, please review

Tech Note 2,

Multi-Point Feature and CMM Inherent Errors. |

| |

Stylus Manager, Features, Menus and Support Tools |

| |