|

Introduction

Feature Averaging provides the user with the tools

to evaluate a critical form dimension during the part inspection run and

determine if it exceeds the upper or lower tolerance band. Features that

are supported are: Circle, Sphere and Cylinder.

During the part inspection, Geomet will review the Diameter or Radius

and compare it against the tolerance band. If it exceeds the tolerance

band and remains within the established evaluation zone, Geomet will

automatically rerun the feature up to the cycle limit and average all

the reported form values.

Establishing the Default Settings for Feature

Averaging

You can establish basic guidelines for the two

parameters that Feature Averaging will use. To create the defaults, go

to the System Options by pressing the < F9 > key.

Locate the two setting keys:

Feature Averaging default cycles

Feature Averaging default

limit

Set defaults for these two averaging

characteristics. The default cycle instructs Geomet to rerun the

same feature up to this entered cycle count. The default limit

establishes a zone outside the tolerance limits that if

the measured feature falls in this zone, then a rerun will automatically

take place. For example: if you are measuring a diameter with a nominal

value of 1.000” and a tolerance of ± .001 your limits would be 0.999 -

1.001. The evaluation zone entered as 0.0002" would be 0.9988 - 0.999

and 1.001 - 1.0012 or .0002 outside tolerance limits. The default values

entered here are only a starting point, you can change the values on a

feature by feature basis through the tagging operation listed below.

Feature Average Tagging

|

| figure

2, Tagging |

To start the feature tagging process, measure a

qualifying feature complete with motion. Apply tolerance to the feature

size. Highlight the feature and right-click your mouse to pop-up the

feature menu. Choose Configure Feature Averaging and the Feature

Averaging dialog will appear.

Note: If you do not see a Configure Feature

Averaging in the menu, it can be caused by two conditions. First, the

feature must have a tolerance applied to the size attribute. The second

reason is that this tool requires Direct Computer Control (DCC).

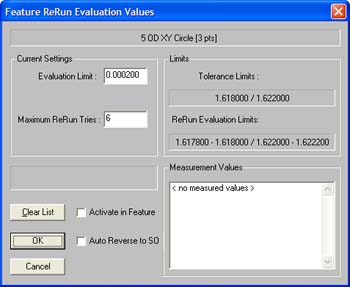

Feature Averaging Setup Dialog

This setup dialog establishes the operating

parameters for Feature Averaging on a qualifying Circle, Sphere or

Cylinder. There are three settings which you can set to control the

rerun characteristics.

|

|

figure 3, Feature Average Setup Dialog |

Evaluation Limit

The zone outside the tolerance limits where Geomet

will determine whether to rerun a feature. As previously mentioned, this

applies only to the Diameter or Radius of the feature.

Maximum Rerun Tries

The number of ReRun cycles Geomet will try to do on the feature. When Geomet

enters a rerun cycle it retains the previous actual dimension and adds it to

the final record. Once it completes the rerun cycle, Geomet will average out

all runs to determine if it falls inside the tolerance zone.

If the average falls inside the tolerance zone, Geomet will

cease the reruns at the current cycle and report the feature. If the average

falls outside the evaluation zone, Geomet will consider the feature

out-of-tolerance and cease the rerun cycles.

Auto Reverse to SO

This check box is used to force the direction of motion back to the first

Stand Off (SO). The first SO is the starting point for the first measurement

point in the motion map for the feature. On most external features (OD / OR)

you should check this box. When Geomet completes the feature and determines

that a retry is required it will backup though the motion map through all

SOs and IPs to the start of the first measurement point and then rerun the

feature.

If the check is not in place, Geomet will drive from the

current locate directly to the first SO. On most internal features, this

will not cause a problem.

Measurement Values

All currently stored actual measurements will be displayed here for review.

Activate in Feature

When this is checked, Feature Averaging is active for this feature.

Feature Averaging during a Part Inspection

During a part inspection, Geomet constantly monitors every

feature for the Feature Averaging tag. After completing gathering the

required number of data points, Geomet will calculate the diameter or radius

and compare it to the evaluation zone. If it is found that the result falls

inside the evaluation zone, Geomet will return store the actual value and

display it on the monitor and return to the first SO and rerun the feature.

Once the rerun is completed, Geomet will then average the

first and second actual values and perform on of the following:

-

Average falls inside tolerance zone: The feature

is completed and the results are added to the report.

-

Average falls inside evaluation zone: Geomet adds

the new actual to the list and attempts another rerun. This cycles

continues until either a) or c) conditions exist or until maximum

allowed cycles is reached. If maximum cycles is reached, the feature is

reported as out-of-tolerance.

-

Average falls outside evaluation zone: The

feature is completed and added to the report as a feature

out-of-tolerance.

The results shown in the report for the Diameter

or Radius is the average of all runs. However, the

location reported is that

of the last run. The averaging feature is designed for use on critical size

not for position.

|